Tin can be found everywhere in nature. Smaller amounts are available in rocks, soils, plants, water, and in our bodies. Tin and its alloys are an excellent replacement for metals which are not convenient from an environmental point of view, particularly lead and cadmium. The legislation of some worldwide leading supervisory authorities supports the non-toxicity of tin.

Tin metal products

Pure tin is a silvery-white metal being soft, ductile, and malleable. Tin is classified as non-toxic, it is corrosion resistant, and it has a positive image. A high part (about one third) of the currently produced tin is processed to tinned steel (tinplate) being used for food and beverage cans.

Tin alloys easily with other metals and, therefore, the recyclability of tinplate is of great value. In recent years, tin has been mainly used as solder. Further new fields of application could be tin bullets as ammunition for shotguns and crown caps for vine bottles. These are added to the general consumption.

Solder

There is a particularly big boom in entertainment electronic products and each camera, mobile phone, computer, TV, and radio has a solder containing printed circuit board inside. General concerns in regard to environment and safety caused many manufacturers to use solder for 90% instead of lead.

Tin in tinplate

For a long time, the use of tinplate for food and beverage cans has been a well-established, safe and reliable process. Tinplate is suitable for packages and storing. In some parts of Asia, the consumption per capita of cans corresponds to 1% of the total Western consumption of tin cans.

Tin in chemical agents

The chemical industry shows the greatest increase in tin consumption. The demand for tin in household and industrial paints, plastics, and non-ferrous alloys for use in mechanical engineering is very high.

New fields of application for tin

Due to the continuous research of the International Tin Research Institute, new forms of application were discovered for tin. A great number of well-known producers of beverages in the Western world increasingly use ultrathin steel cans. This new type of application is energy efficient and a good response to the environmental concerns in Europe. Even in sports, golf club manufacturers have switched to tin coatings for the golf club shaft and also an increasing number of suppliers of sporting weapons change their lead to tin ammunition. A typical example for the increasing health awareness is the change from lead containing wine bottle closures to tin containing ones. Furthermore, tin alloys have been developed to replace mercury containing amalgam fillings.

Studies have proven that tin-based stannates can be used every efficiently as a fire-resistant material in polymers which are required for the production of cable sheaths made of PVC, plastics and polyester fabrics. There are also positive results using tin in the development of fire-resistant materials for the paper production.

Casserite (SnO2) is the most important tin ore.

Former trends in the production of tin concentrate (in thousand metric tons)

| Year | China | Indonesia | Malaysia | Thailand | Peru | Brazil | Bolivia | Australia | Portugal |

|---|---|---|---|---|---|---|---|---|---|

| 1970 | 22 | 19 | 74 | 22 | 0.2 | 33.7 | 30 | 9 | -- |

| 1980 | 17 | 32 | 61 | 34 | 1.1 | 7 | 28 | 13 | -- |

| 1990 | 42 | 29 | 21 | 15 | 6 | 43 | 14 | 8 | -- |

| 2000 | 110 | 54 | 6 | 2 | 37 | 14 | 12 | 10 | -- |

| 2006 | 115 | 129 | 2,5 | 0,2 | 38 | 9 | 17 | 2 | 1 |

Tin consumption and future trends

Tin consumption

- The worldwide consumption of tin in 2007: 360,000 metric tons

- Expected growth rate per year: 4%

- China consumes 40% of the output

- This is a deficit in production in regard to the consumption of approx. 40,000 metric tons

- The replacement of plumb lines causes a long-term growth demand as lead will be replaced by tin

- The electronic industry will have, as expected, the biggest growth contribution

- Indonesia, one of the biggest producers, will reduce its production PT Tima, Indonesia’s biggest tin producer, fell short with more than 10,000 metric tons of the expected production 18 smaller melting plants are about to be closed shortly

- If within the next two years, no further mines are ready for operation, a global scarcity would continue in the medium-term.

(Source: 4/11 Australia Mining, monthly magazine)

Future trends

- The use of tin will probably increase since new fields of application will be developed

- Tin has no negative effects

- Probably, other environmentally more harmful metals such as lead, mercury, and cadmium, will be replaced.

Metal trade

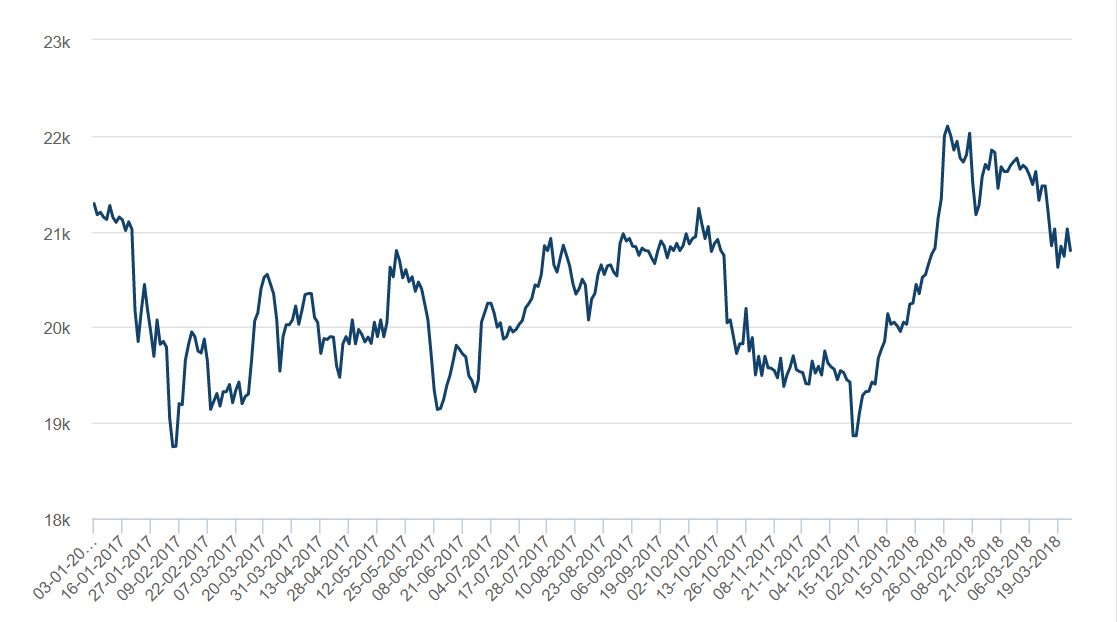

- Tin was one of the original metals (copper, lead, zinc, tin) that were traded at the LME (London Metal Exchange).

- The LME determines mainly the market price mechanism for the tin industry, i.e. an international exchange to hedge purchase and sale.

- Deals are made in parts of 5 metric tons with USD as the main currency

- Traded option contracts for tin are also offered

- Tin selling contracts can be negotiated; the mining companies receive 80% of the concentrate value before exportation against presentation of studying documents.

- The difference of 20% is due after finishing the melting

Conclusion

- Tin is appreciated because of its non-toxicity, corrosion resistance, ability to be alloyed, and its low melting point. More and more, it is recognised as a “green metal”

- Tinplate is a long-lasting, well-established, safe, and reliable material being used in the packaging industry for foods.

- The food industry applies a thin layer of metal on tin cans; this layer is corrosion resistant in order to guarantee a long-term and stable storing of foods from the production site via transport up to the supermarkets and finally in the shelves of the consumers.

- The metal will be recycled for further use after the cans were dumped.

- Tin in solder is important for the electronic industry. Solder is, so far, an alloy of tin and lead. Solder has a low material temperature so that a connection of all components on a printed board card is possible in each and every electronic device. Each computer, each mobile phone and each camera has to do with it. The lead portion in solders came under fire in regard to the environment since a lot of electronic devices are dumped and the toxic characteristics of lead are drained off into the ground. Regulatory requirements reached that the tin portion in solders must be 90%.

- Lead was used as ammunition in Sport Shootings

- Lead played a big role in fishing clubs by its use as weights

- Concerns increased in regard to the environmental pollution of oceans and fresh waters by lead.

- Tin metal has a high density and can be cast and formed in low temperatures.

- It is non-toxic in ocean and fresh water environments

- Tin metal is a “green metal”

The tin price is currently at 20,800 USD/ton.